| Sheet Metal Forming Machines |

| Contact: Mr. John Chang |

| Mob: 0086-139 5619 9239 |

| Tel: 0086-133 0963 1547 |

| E-mail: sumtoinfo@163.com |

| Add: Jinghu District, Wuhu City, Anhui Province, China |

|

| Scan Code Adding WeChat |

|

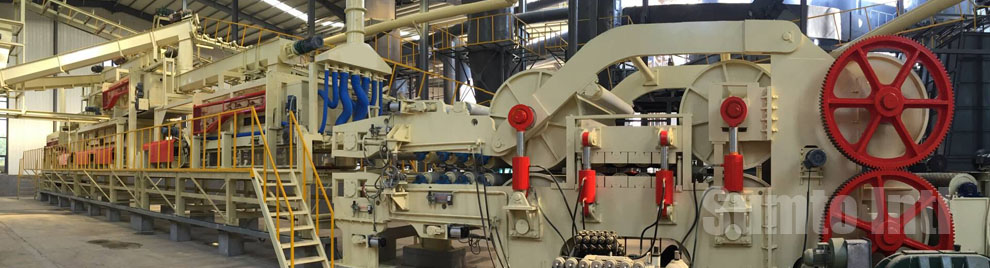

Products Advantage (Automatic Particle Board Manufacturing Machines) - 01 |

| |

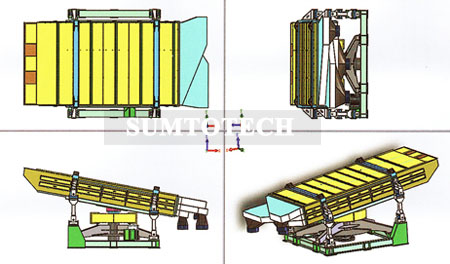

Screen |

|

| Advantage: Strong steel frame, reliable elastic suspension, accurate dynamic analysis, high quality welding material. |

| |

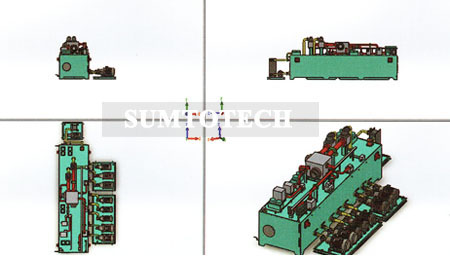

Glue Blender |

|

| Advantage: Uniform and reliable glue sizing, advanced cooling system, high wear-resisting mixing inner, new technology atomizing nozzle, perfect sizing result. |

| |

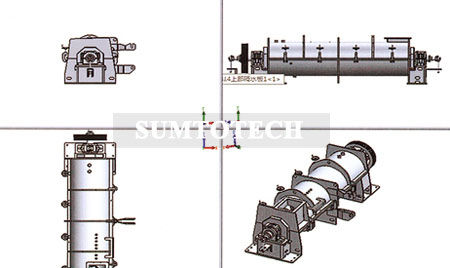

Hydraulic Station System |

|

| Advantage: Reasonable oil circuit layout design, sensitive action, stable pressure, low noise, using high-quality hydraulic components, low failure rate, low power consumption. |

| |

| Working Video Show |

>> View More |

|

| |

| Recommended Readings |

>> View More |

|

Introduction of full automatic particle board production line |

| Sumto is a professional full automatic particle board production line manufacture, particle board line produced by Sumto has capacity 10,000~300,000 cbm/year. The particle board can be produce different size, like 4×8ft, 4×9ft, 5×9ft, 6×8ft, 6×9ft, 6×12ft, etc. ...... |

| |

|

|

Products Advantage (Automatic Particle Board Manufacturing Machines) - 02 |

Rotary Discharger

Advantage: Uniform discharge, good sealing effect, reasonable structure and low power consumption. |

| |

|

|

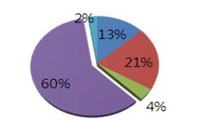

Power Energy Parameter Appraisal Index |

Material preparing section: Approx 690 kw

Drying sieve section: Approx 450 kw

Glue blender section: Approx 120 kw

Forming pressing section: Approx 370 kw

Board trimming section: Approx 450 kw ...... |

|

| |

|